Machine retrofitting involves upgrading existing equipment with modern technologies to enhance performance, extend operational life, and reduce costs compared to purchasing new machinery. This approach not only boosts efficiency but also supports sustainability, making it an ideal strategy for businesses.

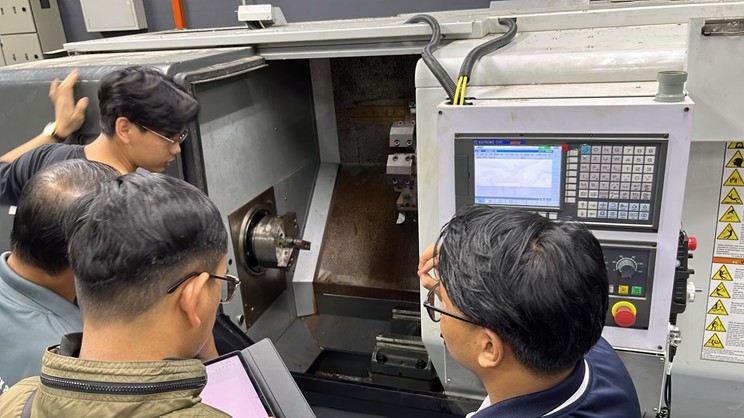

A good example of retrofitting at Sarawak Skills can be seen with Haas machines purchased in 2009 for automation and robotics training. Over time, these machines encountered significant breakdowns due to outdated systems and worn components. Instead of purchasing new equipment, retrofitting was chosen as the solution. The advantages of replacing outdated operating systems and obsolete spare parts with modern alternatives are as follows:

- Enhanced Performance: Faster, more precise, and reliable operations.

- Cost Savings: Retrofitting saved RM 62K on CNC lathes (70% savings) and RM 60K on CNC milling (74% savings).

- Sustainability: Reduced energy consumption, waste, and emissions, supporting ESG compliance.

Retrofitting is one of Sarawak Skills’ key initiatives, aimed at equipping businesses with cost-effective, sustainable solutions. In this respect, Sarawak Skills is committed to collaborating with industries to retrofit machines, improve operational efficiency, and provide training that develops critical skills for the workforce of tomorrow.

Additionally, retrofitting promotes hands-on learning, allowing instructors and trainees to work with up-to-date technologies while also improving safety awareness and technical expertise. In summary, machine retrofitting offers valuable financial and environmental benefits, making it a smart, forward-thinking choice for businesses looking to stay competitive and reduce their ecological footprint.